Decrust Gloss

Description

Description

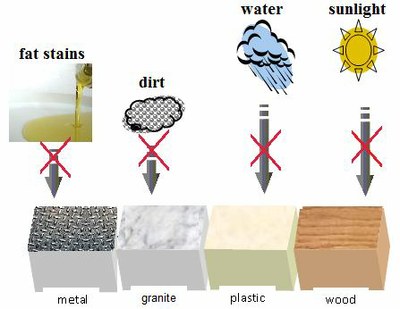

Decrust™ Gloss is a product based on a new formula designed for the cleaning, polishing, protection of many kind of surfaces. The application of the product is intended to protect the surface against harsh environmental

conditions and make the surface resistant to such conditions. Decrust™ Gloss offers excellent protection against UV-light, humidity and dirt. Decrust™ Gloss is an ultra-modern formulation imparting hydrophobic properties by defined surface active agents together with organic saturated monomers (OSM’s). Decrust™ Gloss is a product based on a new formula designed for thecleaning, polishing, protection of many kind of surfaces. The application ofthe product is intended to protect the surface against harsh environmentalconditions and make the surface resistant to such conditions. Decrust™Gloss offers excellent protection against UV-light, humidity and dirt.Decrust™ Gloss is an ultra-modern formulation imparting hydrophobicproperties by defined surface active agents together with organic saturatedmonomers (OSM’s).

Application Background

Application Background

DecrustTMGloss has been designed to prevent the typical effects of water, salt, and UV light which every day are challenging the surface of many materials. DecrustTM Gloss has been designed to adsorb such challenges, keeping the surface in a perfect, looking like new condition. DecrustTM Gloss can be used for outside- as well as inside application. DecrustTMGloss has been designed to prevent thetypical effects of water, salt, and UV light whichevery day are challenging the surface of manymaterials. DecrustTM Gloss has been designed toadsorb such challenges, keeping the surface in aperfect, looking like new condition. DecrustTM Glosscan be used for outside- as well as inside application.

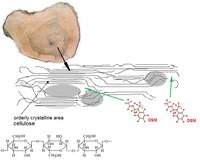

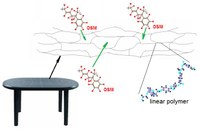

The unusual properties of DecrustTM Gloss are attributable to OSM particles.

In case a rubber, OSM’s interact with the rubber structure under formation of a bonding. Like plasticizers the OSM’s create a new, stronger and more flexible material from the old, none shiny one. In consequence rubber will stay more elastic, wood or plastic will stay looking like new.

After application, DecrustTM Gloss leaves an invisible film on the surface which protects the surface against destructive environmental conditions. If applied regularly the color and looks are protected for life time.

Tires, rafts and other polymer products

Similar to the vulcanization process, OSM’s react with the double bonding of the rubber molecule. This interaction (chemical process) increases the mechanical and chemical resistance of the rubber as illustrated above.

Wooden Fibers

DecrustTM Gloss refreshes wooden surfaces and nourished them attributable to the OSM’s which penetrate the Lignin structure and interact with the wood fibers. In consequence the wooden surface of e.g. furniture is protected against environmental conditions. By this furniture are better protected against mechanical and chemical challenges.

Branched polymers in plastic products

The same effect of a physical proliferation process protection is to be observed with the fibers of various polymers. The color of the polymer surface appears like refreshed. Attributable to the UV-light stabilization of DecrustTM Gloss, such effect will last for a long time.

Application Information

DecrustTM Gloss removes dirt and other impurities from pre-cleaned surfaces. DecrustTM Gloss forms a hydrophobic layer, offering an excellent, long-term protection to various kind and make of surfaces. DecrusTM Gloss protected surfaces repel water and by this are reducing the sticking of dirt and algae.

Attributable to photo oxidation inhibitors, DecrustTM Gloss protects against the effects of UV light radiation. DecrustTM Gloss provides a molecular shield to the treated surface.

Usage

DecrustTM Gloss is offered as ready to use product for the application on many kind of surfaces. The concentration of the active ingredient is 90 wt.%. The application of DecrustTM Gloss is as simple as effective: just wipe on and let dry. Short wiping afterwards will optimize the gloss.